Help for a tangled bobbin mess

Sewing is a wonderful hobby that can bring peace and joy to your life. Whether you’re working on a quilt, a dress, or a simple project, the feeling of accomplishment when you see the finished product is unparalleled. However, sometimes when you’re working alone, things can go wrong and ruin your perfect moment. Have you ever had to google How to fix bobbin tension?

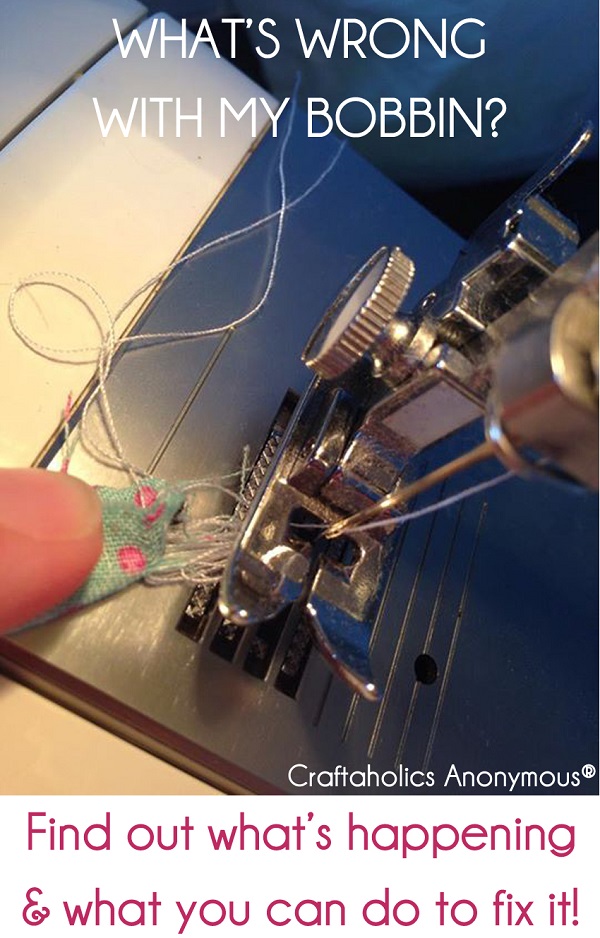

One of the most common issues sewers face is when their bobbin becomes tangled. This can be frustrating, especially when you’re in the middle of a project and don’t know what to do. But don’t worry, help is at hand! Linda from Craftaholics Anonymous has some great troubleshooting advice to help you fix the problem and get back to sewing.

Linda collected these tips from her Facebook page, where a reader posted a question asking for help with an unruly bobbin. She has helped many sewers before and has a wealth of knowledge to share with you. She has put together a comprehensive guide to fixing tangled bobbins, which will save you time and effort.

Help! My Bobbin Just Blew Up! by Craftaholics Anonymous

[photo from Craftaholics Anonymous]

Here are my own top tips for fixing that jammed-up, messed up Bobbin:

Check the thread tension: If the bobbin thread tension is too tight, it will cause the thread to twist and tangle.

Use high-quality thread: Good-quality thread is smoother and less likely to tangle.

Keep your machine clean: Dust and debris can accumulate in your machine, causing issues with the bobbin thread.

Re-thread the machine: If your bobbin is tangled, you may need to re-thread the machine to resolve the issue.

Slow down: If you’re sewing too quickly, it can cause the bobbin thread to tangle.

Fixing tension on your sewing bobbin is an important step in ensuring that your sewing machine produces clean and even stitches. Here are some steps you can follow to adjust the tension on your bobbin:

Gather tools: Before you begin, make sure you have the following tools: a small screwdriver, a thread spool, and a piece of fabric.

Identify the tension disk: The tension disk is usually located near the bobbin case and controls the amount of tension on the thread as it is pulled from the bobbin. It may be a small metal disk or a spring-loaded mechanism.

Test the tension: Take a piece of fabric and sew a few stitches. If the bobbin thread is too loose, the top thread will appear on the underside of the fabric. If the bobbin thread is too tight, the top thread will appear on the top of the fabric and the stitches will be too tight.

Adjust the tension: If the bobbin thread is too loose, turn the tension disk clockwise to increase the tension. If the bobbin thread is too tight, turn the tension disk counterclockwise to decrease the tension. Make small adjustments and test the tension after each adjustment.

Test the tension: Repeat the sewing test on the piece of fabric to see if the tension is now correct. If it is still not right, repeat the adjustment process until the bobbin thread is at the right tension.

Secure the tension: Once you have the bobbin thread at the right tension, secure the tension disk with the screwdriver.

By following these steps, you should be able to adjust the tension on your bobbin and produce clean, even stitches. It’s a good idea to regularly check and adjust the tension on your bobbin to ensure your sewing machine is working at its best.

Happens to me more often than I would like to admit! And I’ve been sewing for 45 years!

This happened to me (more times than i care to mention) But i found that if i changed my cotton to a polyester thread and a new needle and so far it has worked, no more nesting

My problem is thread broken off by me trying to clear a thread caught in mechanism snd now machine bound up. How/what do I do to get that thread out snd unfreeze my machine??